Frequently Asked Questions

Here we answer our customers' frequently asked questions about polishing and grinding:

What is the Difference Between Polishing and Buffing?

The terms "polishing" and "buffing" designate two technically different processes during surface finishing. Both processes are about reducing the roughness of the surfaces to a minimum without changing the workpiece geometry that has previously been defined through cutting and grinding. Consequently, polishing and buffing must not remove significant amounts of material.

Polishing

Polishing is a finishing process that involves the use of an abrasive that’s firmly connected with a carrier such as sanding belts. Polishing therefore is a shape cutting process to smooth surfaces, remove scratches and indentations and scale the surface. The resulting polishing lines must be fine enought to be effectively removed during subsequent buffing.

Buffing

It is assumed that buffing is essentially based on two distinct processes: On the one hand, the roughness peaks remaining from the previous polishing steps are gently removed with the help of fine abrasive grains. On the other hand, the workpiece surface is deformed in microscopic areas by the abrasive grains striking it at high speed, which results in a smoothing of unevenness.

Buffing ist performed in subsequent steps with rotating wheels, which are usually made of natural materials and are impregnated with fine polishing pastes. There are two main steps involved in buffing:

- Coarse cut buffing removes the fine polishing lines by applying high levels of energy until a smooth and homogeneous surface appearance is created. The most suitable polishing tools for this process step usually are brushes or polishing discs manufactured of resistant natural raw materials such as tampico or sisal fibers together with heavy-cut polishing compounds.

- Finish buffing is the last and finest step in surface finishing, which is carried out using cotton polishing wheels at low working pressure and short process times together with super-finish polishing compounds. This will level out any microfine lines remaining after the cut-buff process and thereby smooth the surface. This then creates the desired brigth luster finish.

How do I Properly Dress a Buffing Wheel?

Careful preparation of the buffing tool is a prerequisite for an optimal buffing result. Because the finer the fiber structure of the disc, the better the surface quality. Unused and untreated cotton buffing discs do not accept the polishing paste well which leads to unsatisfactory results. For this reason, the surface of buffing discs must be carefully roughened, until a fine velour of microfibers has emerged. Please follow our instructions for the trimming of buffing wheels.

Which Cut-Buffing Wheel is Right for my Project?

When pre-polishing, it is very important that the tool is precisely matched to the polishing project. Cut-buffing discs from EICKELIT consist of high-quality natural materials such as sisal fabric, sisal cords, sisal-cotton mixtures or Tampico-fibre. Thanks to a variety of designs and our universal impregnation system, the EICKELIT pre-polishing discs can be optimized for any challenge.

Which Impregnation Should I Use for Cut-Buffing?

The EICKELIT impregnation system allows an individual optimization of the service life, aggressiveness and absorption capacity of polishing compounds. Please select the most suitable impregnation for your application according to the following table:

| Impregnation | Stages | Properties | Application |

|---|---|---|---|

| ImpregnationGreen | Stages1 | Propertiessupple / non-smearing | ApplicationNon-ferrous metals |

| ImpregnationViolet | Stages1 | Propertieselastic / sticky | ApplicationUniversal |

| ImpregnationBlue | Stages1-3 | Propertiesvery soft -> soft | ApplicationAluminium |

| ImpregnationRed | Stages1-3 | Propertiessoft -> medium-hard | ApplicationUniversal |

| ImpregnationYellow | Stages1-3 | Propertiesmedium-hard -> hard | ApplicationSteel / Stainless steel |

| ImpregnationWhite | Stages1-3 | Propertiesvery hard -> extra aggressive | ApplicationStainless steel / titanium |

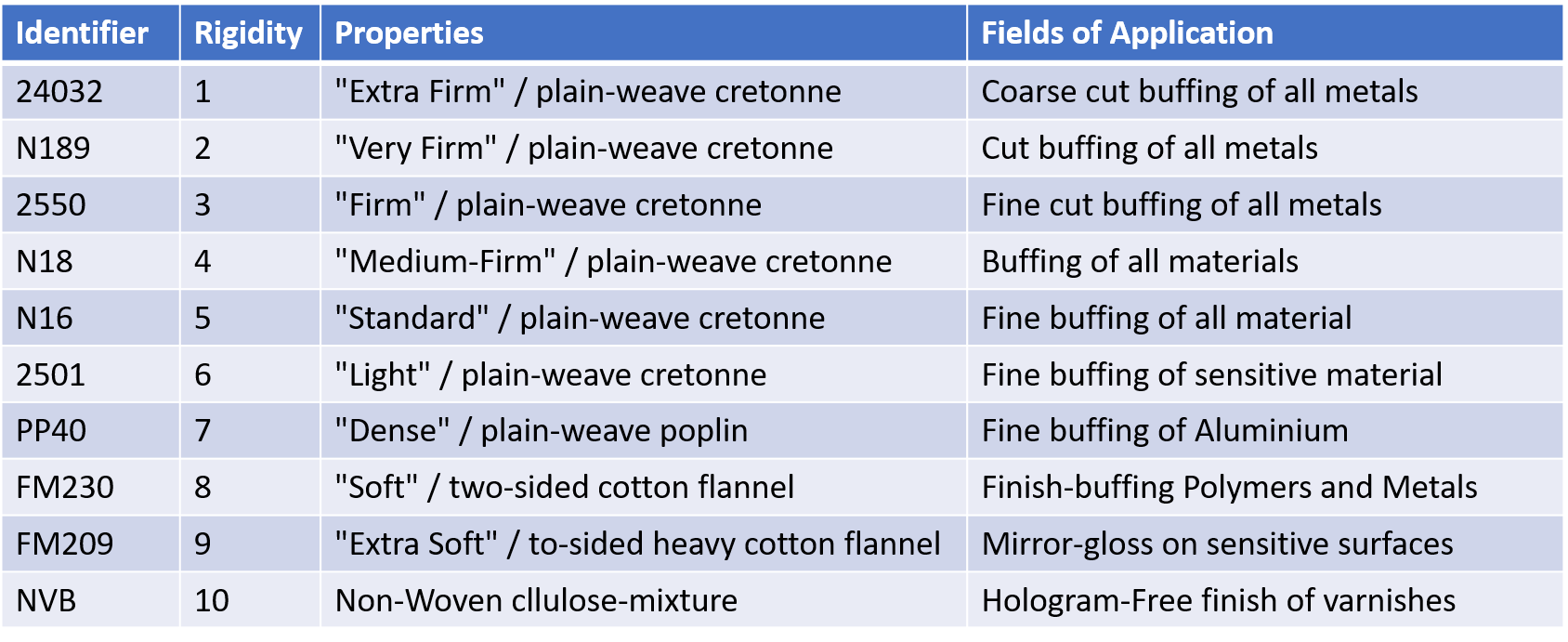

Which Type of Cotton Should I Use?

Please use the following table to select the right type of cotton for your application:

Which Non-Wovens are Available?

The following tables can be used to select the right type of abrasive fleece for your application:

Aluminium Oxide:

| Name | Abrasive | Grit | Grade | Firmness |

|---|---|---|---|---|

| NameAO-002 | AbrasiveCorundum | Grit45 | GradeSuper Coarse | FirmnessExtra Reinforced |

| NameAO-003-MG | AbrasiveCorundum | Grit80 | GradeExtra Coarse | FirmnessStandard |

| NameAO-003 | AbrasiveCorundum | Grit100 | GradeCoarse | FirmnessStandard |

| NameAO-004 | AbrasiveCorundum | Grit180 | GradeMedium | FirmnessStandard |

| NameAO-004-HD | AbrasiveCorundum | Grit180 | GradeMedium | FirmnessReinforced |

| NameAO-004-SD | AbrasiveCorundum | Grit180 | GradeMedium | FirmnessExtra Reinforced |

| NameAO-006 | AbrasiveCorundum | Grit240 | GradeFine | FirmnessStandard |

| NameAO-006-HD | AbrasiveCorundum | Grit240 | GradeFine | FirmnessReinforced |

| NameAO-007 | AbrasiveCorundum | Grit320 | GradeVery Fine | FestigkeitStandard |

| NameAO-007-HD | AbrasiveCorundum | Grit320 | GradeVery Fine | FirmnessReinforced |

| NameAO-007-SD | AbrasiveCorundum | Grit320 | GradeVery Fine | FirmnessExtra Reinforced |

Silicon Carbide:

| Name | Abrasive | Grit | Grade | Firmness |

|---|---|---|---|---|

| NameSC-004 | AbrasiveSilicon Carbide | Grit180 | GradeMedium | FirmnessStandard |

| NameSC-006 | AbrasiveSilicon Carbide | Grit240 | GradeFine | FirmnessStandard |

| NameSC-007 | AbrasiveSilicon Carbide | Grit320 | GradeVery Fine | FirmnessSoft |

| NameSC-009 | AbrasiveSilicon Carbide | Grit600 | GradeUltra Fine | FirmnessExtra Soft |

Which Buffing Tool suits my Application?

Please contact us directly during our business hours, we will be happy to advise you personally. Outside of our business hours you are welcome to leave us a message, we will get back to you back as soon as possible.

Does EICKELIT Offer Advice on Polishing?

- Please read our tips on polishing first

- We would be happy to advise you on your polishing project without obligation. Please give us a call during our opening hours or send us a message, we will get back to you as soon as possible. We are looking forward to your contact.

At what speed should I work?

The cutting speed of the polishing disc, which is critical for the polishing result, depends on both the speed of the drive and the diameter of the polishing disc. This controls the energy input into the surface of the workpiece and therefore the effectiveness of the polishing process. It should be noted here:

- Excessively high speeds lead to overheating of the tool and workpiece, which reduces the service life of the polishing disc and results in surface defects.

- Speeds that are too low are at the expense of efficiency.

The optimum cutting speed to be determined in tests for the respective project objective therefore determines whether and how quickly the respective project objective can be achieved. It is influenced in particular by the material properties of the workpiece to be machined, der the type of tool selected and the specification of the polishing pastes used.