Safety instructions for system operators

System operators of grinding and polishing equipment are fundamentally obliged to effectively minimize all existing potential hazards. For this he must take suitable protective measures on the basis of a regular safety assessment of the workplaces in order to design the work environment in accordance with the state of the art.

Handling and storage of rotating polishing discs

Polishing discs should be stored in a dry, clean and cool place. To avoid imbalance, polishing and grinding wheels may only be stored horizontally.

The duroplastic cast and adhesive compounds processed in polishing discs have only limited impact strength. The polishing tools must therefore be handled carefully and must not be exposed to hard knocks or blows or punctiform forces. Polishing discs with damaged cores may no longer be used for safety reasons and must be disposed of.

Clamping rotating polishing discs

Polishing discs must not be operated with an unbalance. The clamping of polishing pads therefore requires effective centering. Polishing discs made of solid material, polishing rings with a fixed core and polishing bodies with a hollow core must be fixed around the center bore using suitable clamping flanges. The clamping flanges should cover at least 20 - 33% of the total pane area or correspond to the diameter of the side covers.

If the diameter of the bore and the machine shaft differ, they are centered using suitable devices: shafts that are too small can be adapted to the bore diameter using centering plates or adapters. Discs with holes that are too small must never be forced over shafts that are too large.

Speeds of rotating polishing wheels

Rotating polishing discs that are operated at too high or too low speeds pose considerable dangers. If the permitted maximum speeds of rotating polishing discs and / or polishing systems are exceeded, there is a risk of death from flying parts due to the risk of breakage. If rotating polishing disks are operated at too low speeds, a workpiece could be picked up spontaneously and accelerated to its peripheral speed.

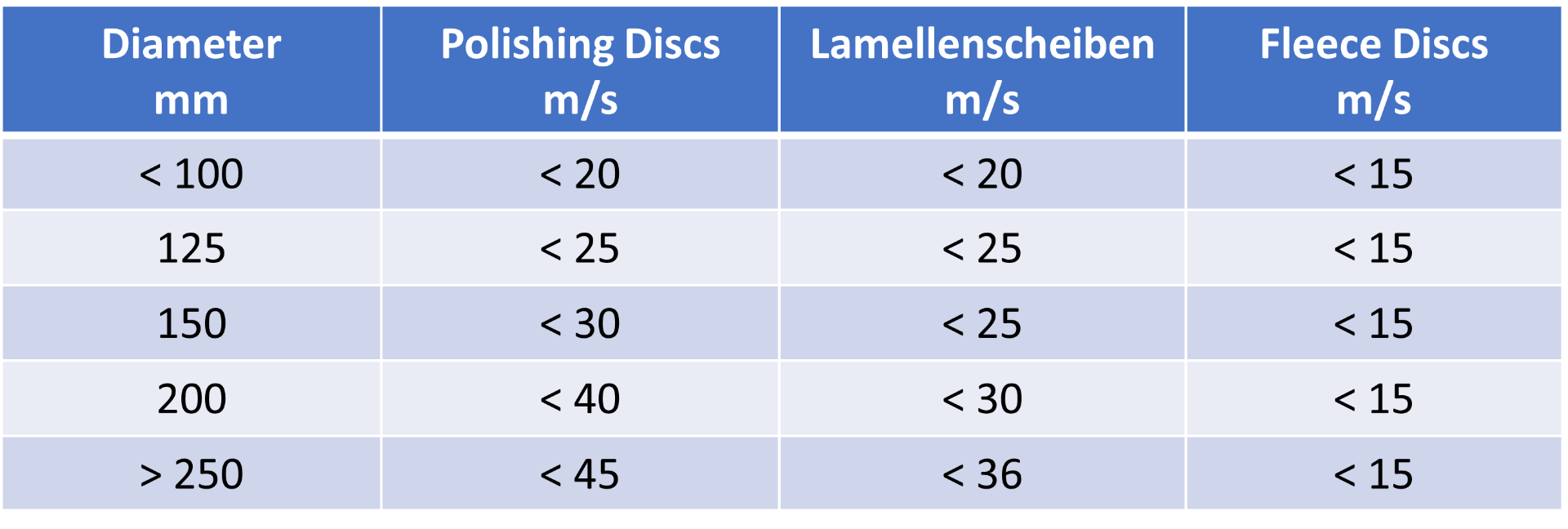

The following table specifies the maximum peripheral speeds and rotational speeds depending on the pulley diameter. The other legal, industry-standard and trade association regulations as well as manufacturer recommendations, which indicate lower values for the maximum circumferential speed, have priority over this list.

Typical speeds of rotating polishing wheels

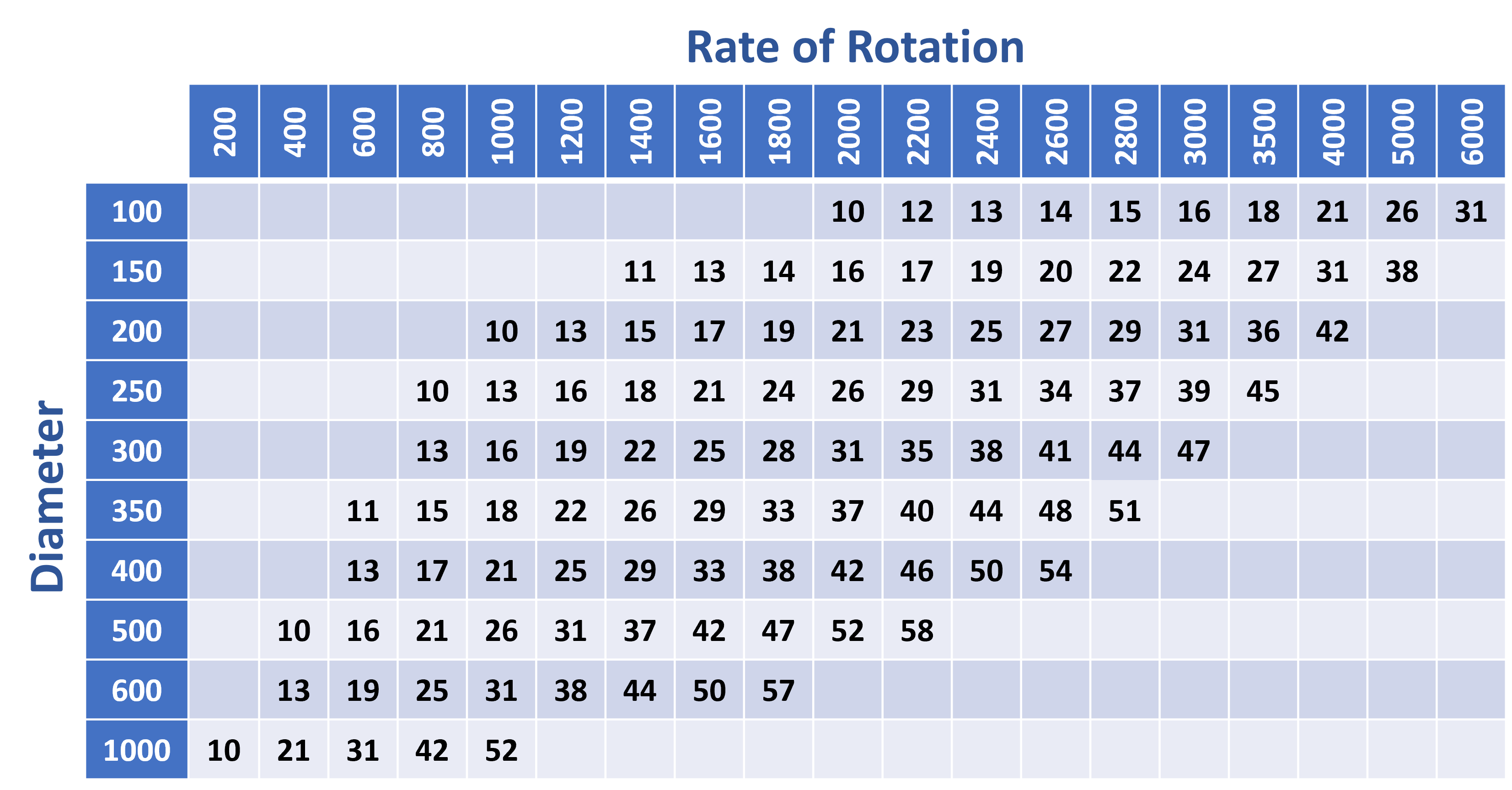

Using the table below, the cutting speeds can be determined as a function of the diameter and the speeds of the polishing wheels (speeds rpm, cutting speeds in m/s):

Safety instructions for shaft diameters

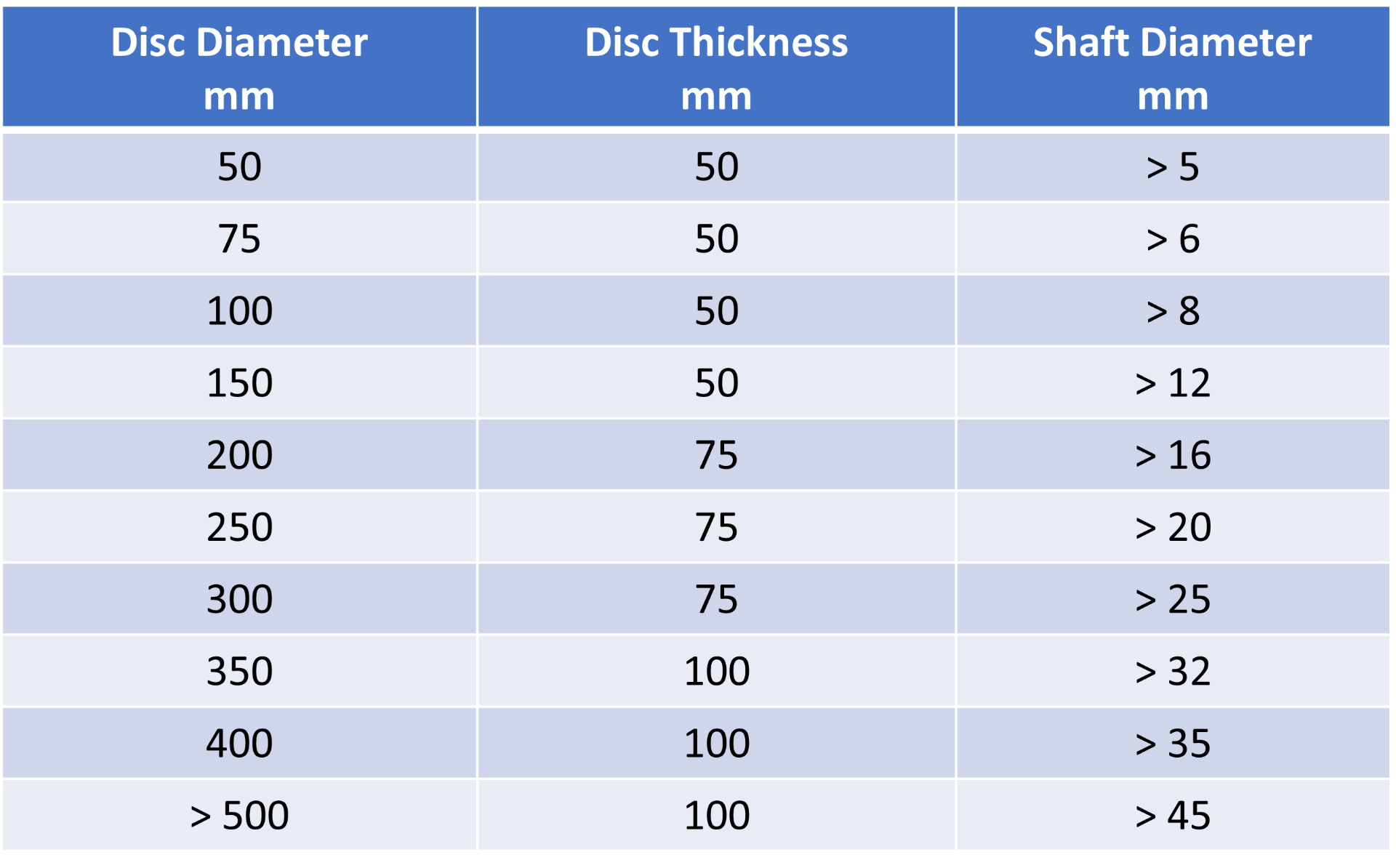

To ensure effective occupational health and safety, the minimum shaft diameter and maximum dimensions of the rotating tools prescribed by the manufacturer of polishing systems must under no circumstances be exceeded or fallen below. The information in the following table is only intended as a guide. Other statutory or trade association regulations as well as manufacturer recommendations that show values that differ from these have priority over this list.

Safety instructions for shank tools

For safety reasons, it is imperative to remain within the stated maximum permitted rotational speed at all times. Safety is only guaranteed if:

- The clamping depth is at least 15 mm

- The specified maximum rotational speed for unsupported shank lengths is not exceeded

Fire and explosion hazards when grinding, brushing and polishing aluminum

When aluminum is processed by grinding, brushing and polishing, combustible dusts are generated which, when mixed with air, can form an explosive atmosphere. If an ignition source effective for the dust / air mixture is present at the same time, an explosion occurs.

When aluminum dust comes into contact with water, for example during wet processing or dust separation in the wet separator, hydrogen gas can be generated. Under normal conditions it forms an explosive atmosphere with air from a volume fraction of approx. 4%. Wherever there is no or insufficient air exchange (e.g. in closed parts of systems or containers), there may be a risk of explosion due to the accumulation of hydrogen.

When aluminum dust comes into contact with oxygen, an oxidation reaction takes place with the development of heat. Fine aluminum particles have a large surface. Freshly created particles are more reactive. Thermally insulating environmental conditions, such as a high proportion of air in the dust, the admixture of cotton fibers by polishing tools, etc., favor the reaching of the ignition temperature of individual waste components in the case of large amounts of waste (the ignition temperature of cotton is 450 ° C). Without an external ignition source, a smoldering fire can occur inside the waste itself or an open fire on the waste surface.

Fire and explosion hazards with material mixtures

When processing aluminum and spark-generating materials in the same systems, it must be ensured that the risk of fire and explosion is avoided. In addition, the simultaneous occurrence of explosive dust / air mixtures and effective ignition sources must be excluded. When machining materials that cause sparks, for example normal steel, gray cast iron, stainless steel (for coarse grinding work such as roughing or cutting) or titanium, sparks are generated which can be effective sources of ignition. Dangerous reactions between the different material dusts and sludges cannot be ruled out either.

Disposal of aluminum dust and sludge

Self-heating when storing or transporting extracted and separated aluminum dusts and sludges must be limited in such a way that no smoldering fires or open fires occur. With fine, dry polishing dust, the risk of self-ignition is particularly high. Sludge that is no longer completely covered by water and thus partially dries on the surface can also heat itself up to the point of spontaneous combustion. The self-heating of the waste can be prevented by the controlled addition of suitable reactive additives or by the complete, permanent storage of the dusts under water. In addition, the tendency to self-heating and thus the risk of self-ignition can be reduced by adding larger proportions of non-reactive substances (e.g. limestone powder for dry dedusting).

- Dry aluminum dusts are to be stored and transported in closed containers. It must be ensured that the penetration of dripping and splashing water into the container is prevented

- Moist aluminum dusts are to be stored and transported in closed containers which are designed in such a way that released hydrogen gas can escape safely. Furthermore, the containers should not have any rust spots

Disposal of other polishing waste

The waste generated during polishing as well as used polishing discs must be collected and given to a certified disposal partner for recycling.

Guidelines and further information

We urgently recommend our customers to observe and implement the relevant trade association rules and guidelines, in particular:

- DGUV 109-001 (grinding, brushing and polishing of aluminum - avoiding dust fires and dust explosions)

- DGUV 100-500 (in particular chapter 2.19: grinding machines / chapter 2.25: grinding and brushing tools)

- DGUV 112-995 (use of protective gloves)

- DGUV 209-002 (grinding)

You can find further information about safe grinding and polishing here:

- FEPA (Federation of European Producers of Abrasives) Safety Publications

- The FEPA Abrasives Savety reference pages