Speeds and velocities for polishing wheels

Rate of Rotation

In the case of rotating bodies, the "Rate of Rotation" or "Rotational Speed" is the number of revolutions around its own axis per unit of time. For rotating tools, the rate of rotation is usually specified in revolutions per minute (unit: rpm or 1/min).

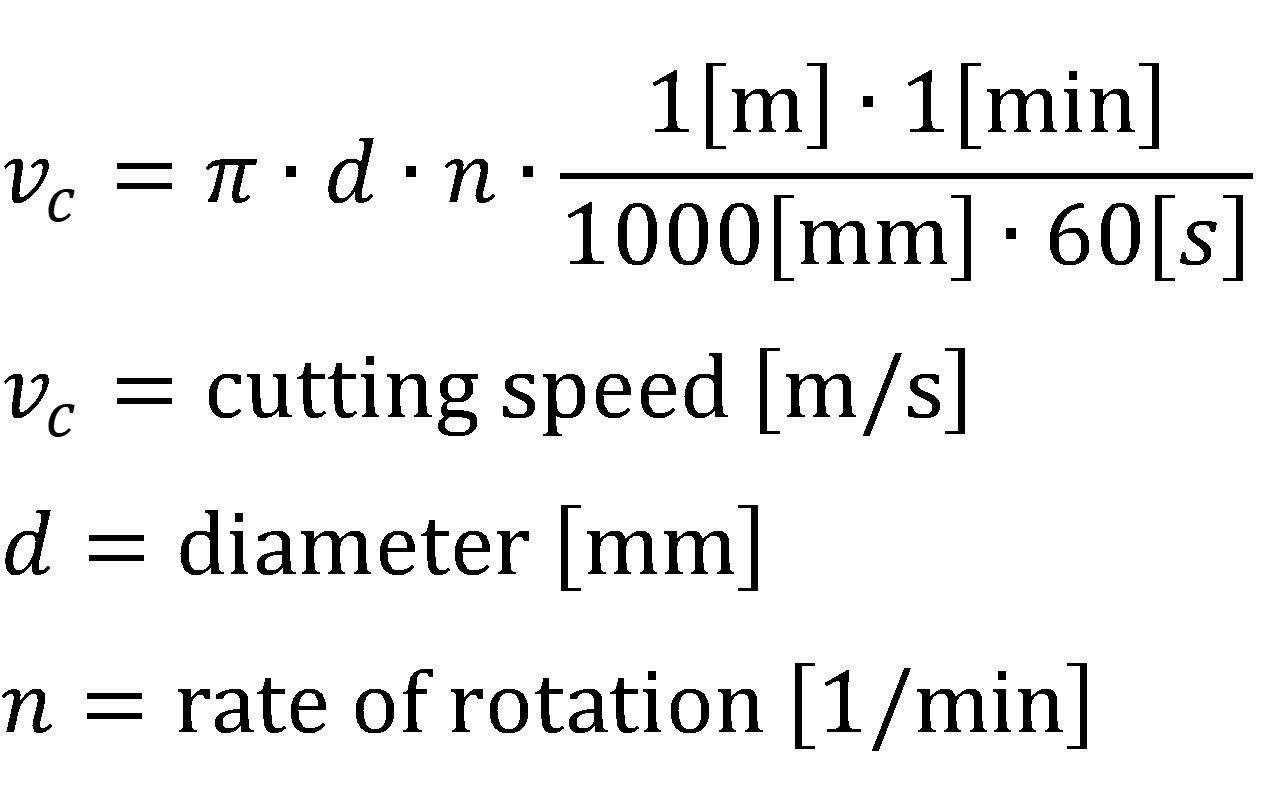

Cutting speed

The Cutting Speed is generally defined as the speed at which the cutting edge of a machining tool is guided through the material. In the case of rotating tools, it corresponds to the peripheral speed. For grinding, cutting and polishing wheels, this is usually given in meters per second (unit: m/s).

The cutting speed of a rotating tool increases both with the speed and with the diameter. The formula for calculating the cutting speed is therefore:

[Example: a speed of approx. 3,185 rpm is required for a tool with a diameter of 150 mm to achieve a cutting speed of 25 m/s.]

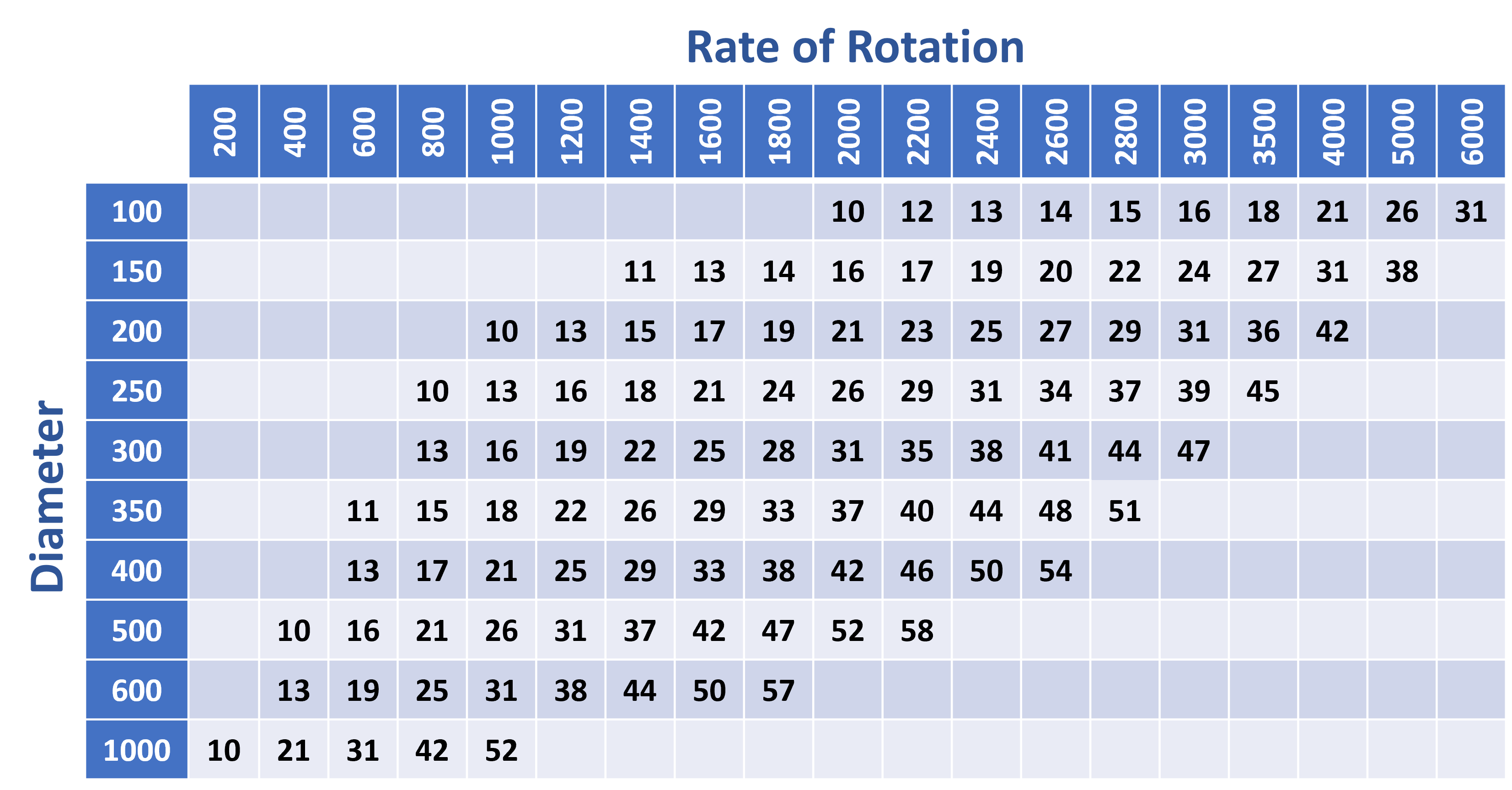

Using the table below, the cutting speeds can be determined as a function of the diameter and the speeds of the polishing wheels (speeds in rpm, cutting speeds in m/s):

Optimum Cutting Speed

The energy input into the surface of the workpiece and thus the effectiveness of the polishing process is controlled via the cutting speed of the polishing wheel. On the one hand, speeds that are too high can lead to overheating of the tool and workpiece. This can result in reduced pad life and surface defects. On the other hand, speeds that are too low are at the expense of effectiveness. It therefore depends to a large extent on the optimal cutting speed whether and how quickly the respective project goal can be achieved.

The optimum cutting speed depends in particular on the material properties of the workpiece to be machined, the type of tool selected and the specification the polishing pastes used. However, since the determination of optimal process parameters in systematic test series is very complex, the technical know-how of experienced practitioners is to this day the primary source of knowledge when optimizing the polishing process.

As a starting point for your own polishing experiments, please refer to the following table for the typical cutting speeds for different materials and polishing steps. In case if you need assistance, we would be happy to advise you on how to optimize your polishing process. Please send us a message using our contact form and we will get back to you as soon as possible.

| Process | Surface | Material | Tool Type | Min m/s | Max m/s |

|---|---|---|---|---|---|

| Process Grinding / Matting | Surface Metals / Plastics | Material Abrasive Fleece AlOx / SiC | Tool Type Flap-Wheels / Corrugated Non-Woven / Abrasive Discs | Min m/s 10 | Max m/s 25 |

| Process Cut-Buffing | Surface NF-Metals | Material Sisal-Cotton / Extra Firm Cotton | Tool Type SB-VR / Cotton Buffs | Min m/s 35 | Max m/s 50 |

| Process Cut-Buffing | Surface Steel / Stainless / Chromium | Material Sisal-Fabric / Sisal-Cotton | Tool Type SB-XL / Si-W-PK / SB-3 / SB-VR Impregnated / Natural | Min m/s 30 | Max m/s 35 |

| Process Cut-Buffing | Surface Thermoset | Material Firm Cotton | Tool Type KONSTANT / REX | Min m/s 20 | Max m/s 30 |

| Process Cut-Buffing | Surface Thermoplastic | Material Light Cotton | Tool Type KONSTANT / REX | Min m/s 10 | Max m/s 15 |

| Process Cut-Buffing | Surface Varnishes | Material Firm Cotton | Tool Type KONSTANT / REX | Min m/s 15 | Max m/s 25 |

| Process Colouring | Surface NF-Metals | Material Medium Firm Cotton | Tool Type Buffing Discs / KONSTANT | Min m/s 40 | Max m/s 60 |

| Process Colouring | Surface Steel | Material Firm Cotton | Tool Type KONSTANT / EFFEKTA | Min m/s 25 | Max m/s 35 |

| Process Colouring | Surface Plastics / Varnishes | Material Medium-Firm Cotton | Tool Type EFFEKTA "100 % seamless" | Min m/s 15 | Max m/s 25 |

| Process Finishing | Surface NF-Metals | Material Light Cotton / Soft Flanell | Tool Type Buffing Discs / EFFEKTA | Min m/s 45 | Max m/s 60 |

| Process Finishing | Surface Steel | Material Soft Flanell | Tool Type KONSTANT / EFFEKTA | Min m/s 25 | Max m/s 35 |

| Process Finishing | Surface Thermoplasts | Material Extra Soft Flanell | Tool Type EFFEKTA "100 % seamless" | Min m/s 10 | Max m/s 15 |

| Process Finishing | Surface Varnishes / Thermoset | Material Extra Soft Flanell | Tool Type EFFEKTA "100 % seamless" | Min m/s 15 | Max m/s 25 |

Safety Instructions

The maximum cutting speed of a rotating tool is limited by the specific mechanical properties of the tool design. Because above critical cutting speeds there is a risk of tool breakage if, for example, the shearing forces that occur exceed the strengths specific to the tool. However, tools that are operated at too low a speed also pose a risk if they grip workpieces, accelerate to peripheral speed and finally throw them away from the tool.

Therefore, please be sure to observe the safety regulations of your machine manufacturer as well as our safety instructions for system operators.