Abrasive fleece for polishing wheels

Properties of abrasive fleece

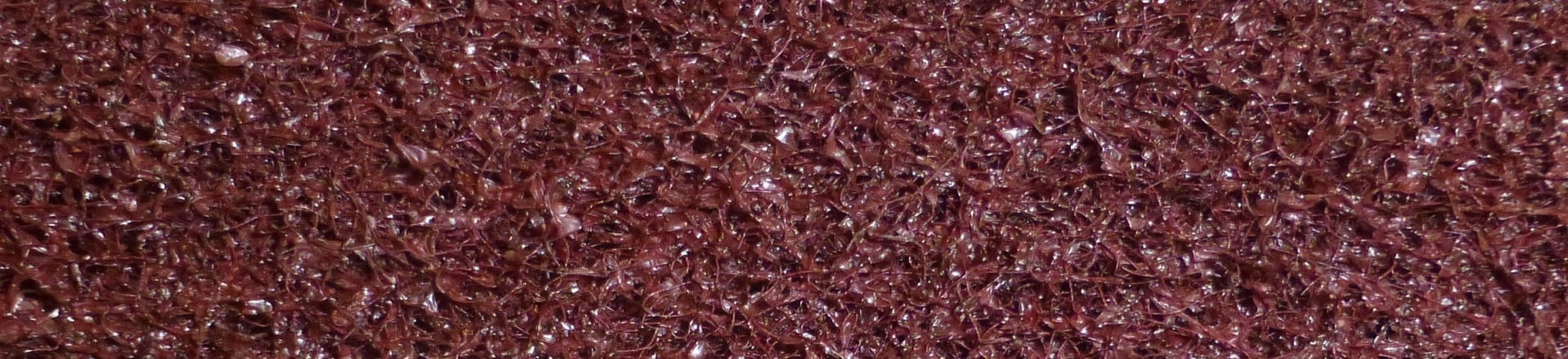

Analogous to textile-bonded abrasives, abrasive fleece consists of a base material onto which the very hard abrasive particles are bonded with the help of special synthetic resins. Usually, the active substances are either so-called silicon carbide ("carborundum") or aluminium oxide ("corundum"). More rarely, abrasives containing zirconium or diamond are used.

The basis for the production of abrasive fleeces is a non-woven web made of synthetic fibres. In the industry, both the cheaper polyester fibres and the nylon fibres, which are preferred due to their better mechanical and thermal stability, are used. Abrasive particles are then sprayed onto this tangled nonwoven in a complicated multi-stage process and fixed there with special synthetic resins. The exact selection of the physical and chemical properties of these binders determine the flexibility and colour of the resulting abrasive fleece. Due to this wide range of variations, we are able to meet even the most unusual application requirements with the help of our non-woven abrasive polishing discs.

Abrasive Fleece used by EICKELIT

In order to achieve the goal of maximum efficiency with a long service life, we at EICKELIT only use high-quality abrasive fleeces based on polyamide without polyester components. Thanks to our European supply sources, which have been established for decades, we have a wide range of abrasive fleeces that are always available in the same quality specifications. Our diverse abrasive fleece polishing tools are manufactured according to a precisely defined system of strength levels and grit sizes between grit P45 and P600. In addition, on this basis we can precisely set our fleece lamella polishing discs in 4 increasing strength levels (H1/H3/H5/H7). As a result, EIKELIT grinding fleece polishing discs always meet any application-related challenge.

Corundum / Aluminiumoxide (AO)

Corundum consists of > 95 % crystalline aluminium oxide and is the most commonly used abrasive on non-woven and abrasive cloths. The essential property of corundum is that the crystallites become harder and thus also more brittle with increasing degrees of purity. Due to the high mechanical loads during grinding, this has a negative effect on the service life of abrasives as well as on the uniformity of the grinding pattern. Therefore, the toughness of corundum is increased by additionally doping the melts with different metal oxides. This improves the longevity of the abrasives and ensures a more balanced grinding pattern overall. For this reason, highly doped and therefore tough corundum is used in abrasive fleeces so that the widest possible range of applications can be covered

EICKELIT uses a wide range of abrasive fleeces with corundum as abrasive for its polishing tools:

| Name | Abrasive | Grit | Grade | Firmness |

|---|---|---|---|---|

| NameAO-002 | AbrasiveCorundum | Grit45 | GradeSuper Coarse | FirmnessExtra Reinforced |

| NameAO-003-MG | AbrasiveCorundum | Grit80 | GradeExtra Coarse | FirmnessStandard |

| NameAO-003 | AbrasiveCorundum | Grit100 | GradeCoarse | FirmnessStandard |

| NameAO-004 | AbrasiveCorundum | Grit180 | GradeMedium | FirmnessStandard |

| NameAO-004-HD | AbrasiveCorundum | Grit180 | GradeMedium | FirmnessReinforced |

| NameAO-004-SD | AbrasiveCorundum | Grit180 | GradeMedium | FirmnessExtra Reinforced |

| NameAO-006 | AbrasiveCorundum | Grit240 | GradeFine | FirmnessStandard |

| NameAO-006-HD | AbrasiveCorundum | Grit240 | GradeFine | FirmnessReinforced |

| NameAO-007 | AbrasiveCorundum | Grit320 | GradeVery Fine | FestigkeitStandard |

| NameAO-007-HD | AbrasiveCorundum | Grit320 | GradeVery Fine | FirmnessReinforced |

| NameAO-007-SD | AbrasiveCorundum | Grit320 | GradeVery Fine | FirmnessExtra Reinforced |

Carborundum / Silicon Carbide (SiC)

Carborundum (silicon carbide) is processed on Si-C abrasive fleece, which, in contrast to corundum, consists of very sharp-edged crystals. Silicon carbide is therefore always used when, compared to corundum, fundamentally harder and more brittle properties of the abrasive are required. This is because the Si-C abrasive grains consist of only a few crystallites and have a precisely adjusted size distribution compared to corundum. As a result, abrasive fleeces based on SiC have a much sharper effect compared to aluminium oxide and consequently produce more effective material removal. Due to their hardness, the industry uses these SiC-based abrasive fleeces especially on non-ferrous metals, stainless tool steels as well as on ceramic and mineral materials.

We supply polishing wheels based on silicon carbide in our standard range in the following non-woven abrasive qualities:

| Name | Abrasive | Grit | Grade | Firmness |

|---|---|---|---|---|

| NameSC-004 | AbrasiveSilicon Carbide | Grit180 | GradeMedium | FirmnessStandard |

| NameSC-006 | AbrasiveSilicon Carbide | Grit240 | GradeFine | FirmnessStandard |

| NameSC-007 | AbrasiveSilicon Carbide | Grit320 | GradeVery Fine | FirmnessSoft |

| NameSC-009 | AbrasiveSilicon Carbide | Grit600 | GradeUltra Fine | FirmnessExtra Soft |