Sisal-Cotton Cut-Buffing Shank Tool | Customizable

SB-VR Sisal-Cotton Tool

Thickness: 7- 30 mm

SB-VR polishing tools consist of sisal sheets that are covered with cotton on both sides. In contrast to pure sisal trimmings, SB-VR discs have a slightly polishing effect due to their cotton insert and enable fine grinding and pre-polishing in one operation. SB-VR polishing tools offer the highest back pressure compared to other SB polishing wheels and deliver matt to satin-gloss finishes. These can often be further processed in industrial practice without additional surface finishing.

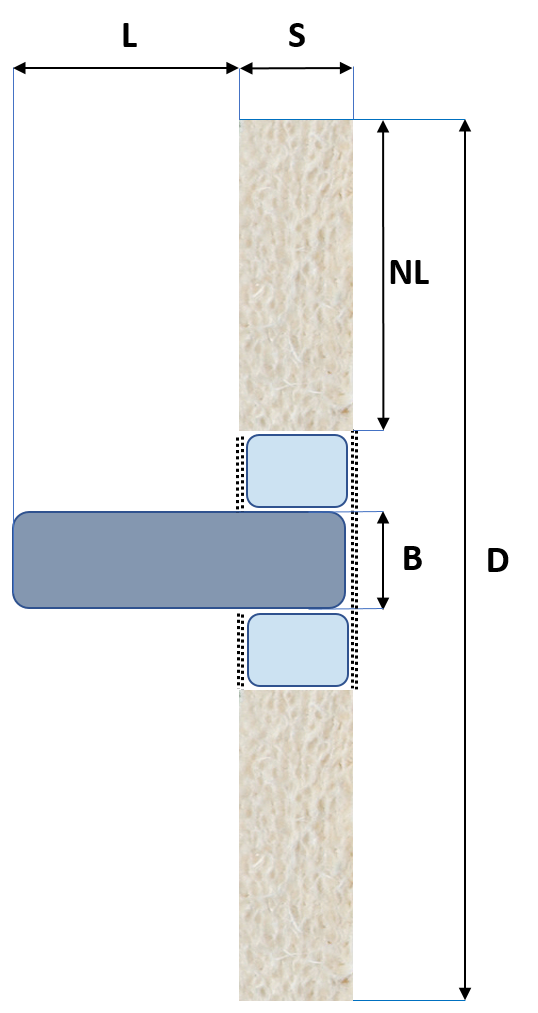

Our shank tools are smaller versions of our EICKELIT polishing discs and are perfect for the precise finishing and refinement of complex geometries.

Product features

- Shaft tool with 10 plies of dense sisal fabric, which is lined with cotton and sewn on both sides

- Concentric quilted circles made of natural linen machine thread, which wears away during the polishing process without leaving any residue and at the same time as the sisal nettle trimming

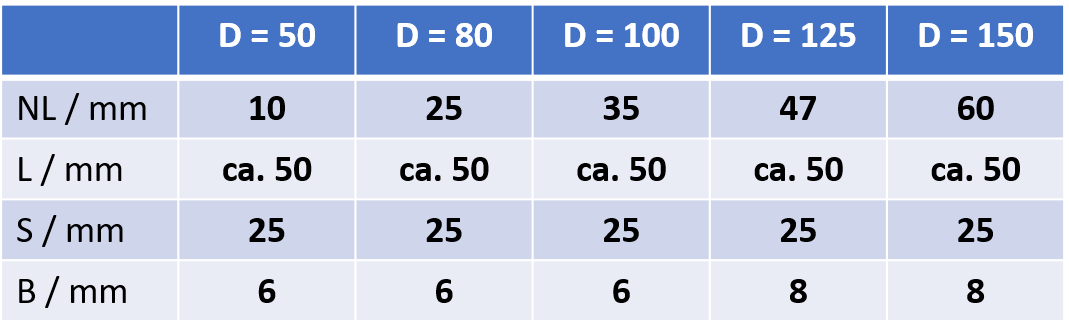

- Diameter configurable 50 - 150 mm

- Thickness configurable 7 - 30 mm

- Cast mandrel with a thickness of 6 mm (50-100 mm tool diameter) or 8 mm (125-150 mm tool diameter)

SISAL-NETTLE COMPOUND

The sisal nettle composite material consists of long-fibre sisal in a dense plain weave. This is twisted at a 45° angle and then covered on both sides with a light cotton nettle. This is fixed with seams made of fine cotton yarn at intervals of around ten millimeters. We process this material in the diverse variants of our EICKELIT SB-X polishing tools.