Buffing Disc | Flannel "Soft" | Configurable

Material: FM230

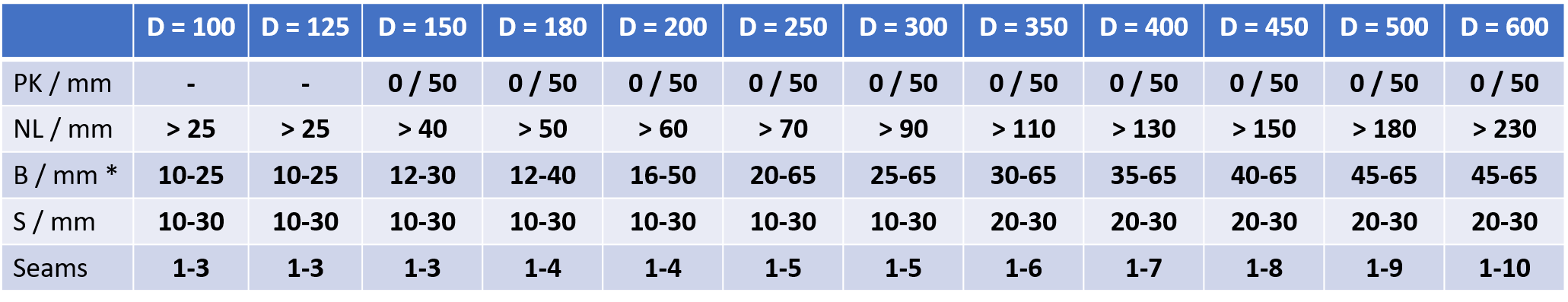

Ø 100 - 600 mm

Thickness: 10 – 30 mm

Our polishing wheels consist of numerous layers of pure raw cotton fabric, which are joined together by high-quality linen machine twine. Thanks to precise calibration and random alignment of the layers, we guarantee low-vibration concentricity and a uniform polishing pattern.

Our "FULL ROUND" polishing wheels have been a proven standard for metal polishing for many years, from pre-polishing to a high-gloss finish. Thanks to our first-class cotton grades, our EICKELIT professional polishing wheels are particularly effective and enable safe and low-dust work.

Molton FM230 is a raw cotton cretonne that is finely napped and has a specific weight of approx. 200 g/m². The finish polishing wheels made from Molton FM230 are particularly suitable for high-gloss polishing of non-ferrous metals, paints and plastics.

PRODUCT FEATURES

- Molton FM230 "Soft" made from 100% pure raw cotton fabric

- Random alignment of the fabric layers

- Individually calibrated discs for low-vibration concentricity

- Working diameter 100 - 600 mm

- Thickness 10 - 30 mm

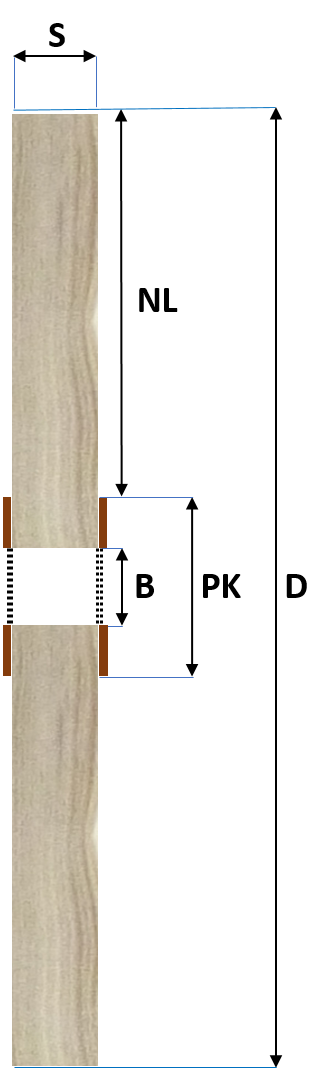

- Freely selectable number (1- 10) of machine-stitched and easy-to-remove topstitching seams made from high-quality linen machine thread without synthetic fibres

- Free choice of bore diameter 10 - 60 mm

- Optionally roughened for immediate use

- Optionally with 50 mm bore reinforcement (from diameter 150 mm)