Buffing Disc | Cotton "Medium Firm" | Configurable

Material: N18

Ø 100 - 600 mm

Thickness: 10 – 30 mm

Cotton Buffing Discs

Cotton buffing discs consist of a multitude of plies of 100% pure raw cotton fabric. The plies are firmly stiched together with high quality linen threads. Due to the random alignment of the plies and their precise calibration, EICKELIT buffing wheels guarantee low-vibration concentricity and thus deliver an absolutely uniform polishing pattern.

Cotton buffing discs are standard tools that have been tried and tested for decades for all work steps on various material - from cut-buffing to a high-gloss finish. Thanks to our premium cotton types, these EICKELIT professional polishing discs are particularly effective and enable safe and dust-reduced work.

Product Features

- 100% pure raw cotton fabric

- Random alignment of the fabric layers and individually calibrated discs for low-vibration concentricity

- Working diameter 100 - 600mm

- Width 10 - 30 mm

- 1 - 10 firmly machine-sewn and easy-to-remove quilting seams made of high-quality linen thread without synthetic fibers

- Bore holes 10 - 60 mm

- Optionally roughened for immediate use

- Optionally with 50 mm bore hole reinforcement (at diameters > 150 mm)

Cotton Quality

For our professional polishing discs, we only use Oeko-Tex® certified fabrics made from raw cotton from controlled cultivation areas. All our cotton cretonnes in plain weave are 100% free from synthetic fibers. For this reason, our polishing discs wear out evenly and are particularly low in dust.

Please follow our link for more information on our cotton fabrics.

Raw Cotton Fabric N18

N18 is a medium-strength raw cotton plain weave fabric with a specific weight of approx. 210 g / m². Buffing tools made of N18 are used in particular for the effective buffing of non-ferrous metals.

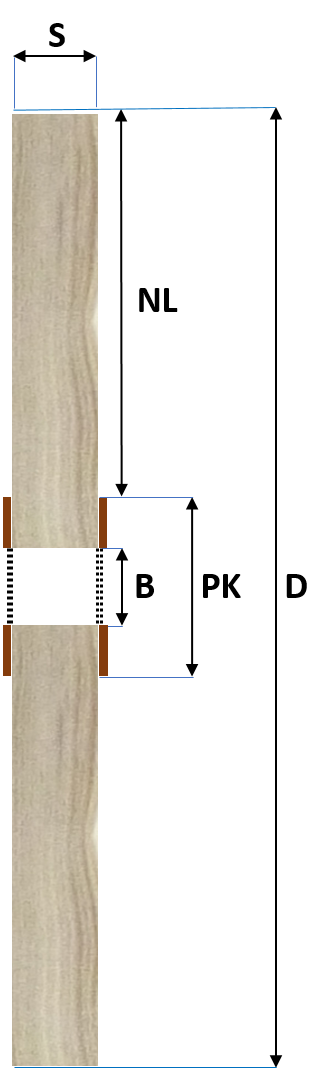

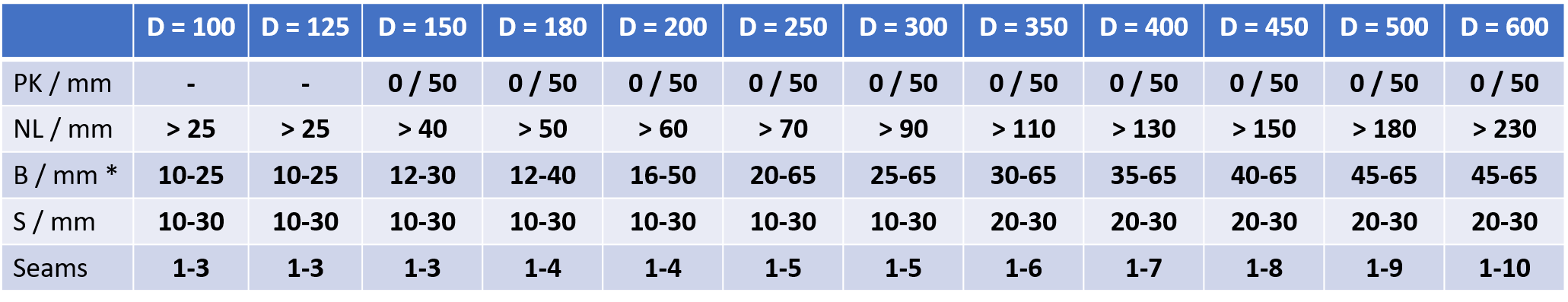

Dimensions

- * Observe the safety regulations for the minimum diameter of drive shafts!

Bore Holes

- We manufacture your desired bore individually for you. We cover every known bore diameter for industrial polishing machines *

- If you need other bore diameters or special adapters (e.g. for hexagonal shafts, with keyways, etc.), we will be happy to manufacture them on request **

* Polishing discs drilled individually at the customer's request are excluded from exchange or return in accordance with our Terms of Cancellation.

** Observe safety regulations for the minimum diameter of drive shafts!

Quilted Seams

- EICKELIT polishing discs have machine-sewn and easy-to-remove concentric quilting circles made of high-quality linen machine thread without synthetic fibers

- Standard polishing discs have only one concentric stitching seam with a diameter of 50 - 80 mm (depending on the disc diameter)

- On request, we produce additional stitching circles in evenly spaced radii *

- We manufacture special spacing distributions on request

* Polishing discs manufactured with individual quilting circles at the customer's request are excluded from exchange or return in accordance with our Terms of Cancellation.

Areas of Application

- Cotton buffing discs are suitable as all-round buffing tools for all materials and finish levels, depending on the material to be buffed and the type of cotton chosen

- Through adding concetric seams, the firmness of cotton buffing discs can be adjusted to individual needs. Quilted cotton buffing discs provide a sound counter pressure for particularly effective polishing

- Quilted cotton buffing discs are preferably used for cut-buffing and high-gloss finish of steel and, in particular, of non-ferrous metals

Heat Build-up of Cotton Buffs

- Due to their high performance with a comparatively low air flow, cotton buffing discs may build-up considerable amounts of frictional heat

- This could lead to lokal overheating and thermal damage of workpiece surfaces and/or the fast and thus non economic consumption of the polishing disc through pyrolysis

- In order to reduce the risk of the overheating of the workpiece and/or the buffing disc, you should adjust the contact pressure with particular care

- Furthermore, you should pursuit the reduction of contact time with the workpiece to the absolute minimum necessary

Trimming Cotton Buffing Wheels

- Careful preparation of the buffing / polishing tool is a prerequisite for an optimal surface result. Please follow our recommendations for trimming cotton buffing wheels

- Used buffing discs should also be dressed again on a regular basis. This is especially true if residues of polishing paste have solidified on the working surface or the buffing wheels are heavily contaminated with material abrasion

General Information on Polishing

- Please follow our link for general tips and advice on polishing

Protective Equipment when Polishing

When grinding and polishing, the work equipment used creates considerable health risks. It is therefore compulsory to wear suitable personal protective equipment for work safety when grinding and polishing. In particular, all rotating polishing and brushing tools may only be operated with suitable covers for reasons of occupational safety.

Wear eye / face protection

The fine dust emanating from polishing is harmful to the eyes. Flying parts can cause serious injuries to the face and eyes.

Wear respiratory protection

Fine dust contaminated with heavy metals and respirable, which can only be retained with suitable respiratory protection, is produced during polishing.

Wear protective clothing

Flying parts can cause sensitive injuries all over the body.

Wear gloves

In general, gloves should be worn when grinding and polishing. If there is a risk of being wound up (e.g. drills, processing small parts, etc.), gloves may be prohibited on the basis of a risk assessment.

Wear ear protection

Due to the noise exposure during grinding and polishing, it is necessary to wear suitable hearing protection on a regular basis.

Details according to Regulation (EU) 2023/988 (GPSR)

Manufacturer

EICKELIT Schleif- und Polierwerkzeuge GmbH, Finkenstr. 66, D-33609 Bielefeld, info@eickelit.de

Responsible Person

Dr. M. Strampfer, Finkenstr. 66, D-33609 Bielefeld, shop@eickelit.com

Universal tool for dressing polishing discs and buffing wheels

Finish Compound for plastics & paints

Color: Beige | Grease Content: Greasy

High-Gloss Finish on Stainless Steel

Colour: Pink | Grease Content: Dry

High Gloss on Aluminium, Brass & Non-Ferrous Metals

Colour: Blue | Grease Content: Medium