EFFEKTA Buffing Wheel Flannel "Soft"

Material: FM230

12 Single Layers / 100 % Seamless

Ø 150 - 600 mm

EFFEKTA® Buffing Wheels

EFFEKTA buffing wheels are high-performance tools for finish-buffing. They are constructed of multiple pleated plies of raw cotton fabric, which ensures a good cooling effect with a very high finish-buffing performance. The soft pleats perfectly adapt to complex surface geometries and provide for random contact patterns. Therefore, EFFEKTA buffing wheels produce particularly uniform surface qualities.

For finish-buffing of particularly sensitive high-gloss surfaces, we manufacture our EFFEKTA polishing discs with high-quality molton trimmings exclusively in 100% seams-free quality.

Cotton Quality

For our professional polishing discs, we only use Oeko-Tex® certified fabrics made from raw cotton from controlled cultivation areas. All our cotton cretonnes in plain weave are 100% free from synthetic fibers. For this reason, our polishing discs wear out evenly and are particularly low in dust.

Please follow our link for more information on our cotton fabrics.

Product Features

- Very soft buffing wheel made of premium raw cotton fabrics with 45° biased weave

- 24 individually pleated plies

- 100% seams-free for highest mirror gloss

- Diameter 150 to 600 mm

- Individual bore from 10 - 60 mm (custom-made products possible on request)

- Calibrated for low-vibration concentricity

- Optionally pre-roughened ready for use

Flannel FM230

Flannel (also called Molleton) is a type of fabric that is made from heavy raw cotton nettle. Through roughening, the fabric structure is specifically weakened, creating a very soft and flexible material with a fine microfiber velor. At the same time, remnants of the abrasive natural impurities are brushed from the raw cotton fabric.

Flannel FM230 is a raw cotton cretonne finely roughened on both sides with a specific weight of approx. 190 g/m². Polishing discs made of flannel FM230 are used in particular for high-gloss polishing on non-ferrous metals, varnish and plastics.

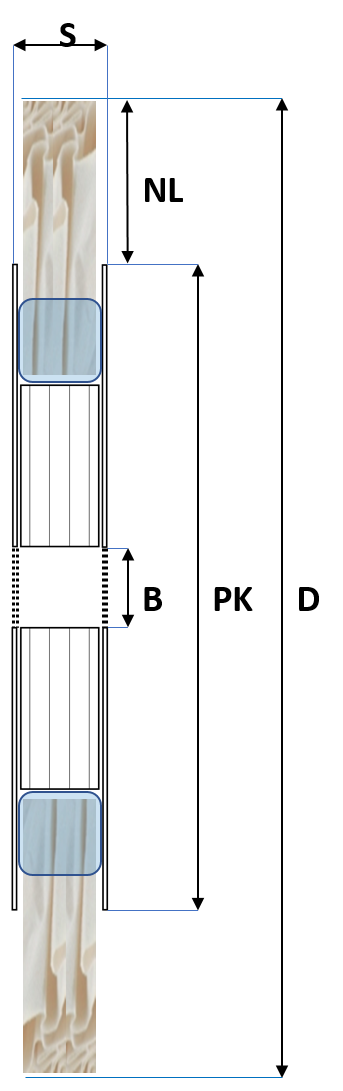

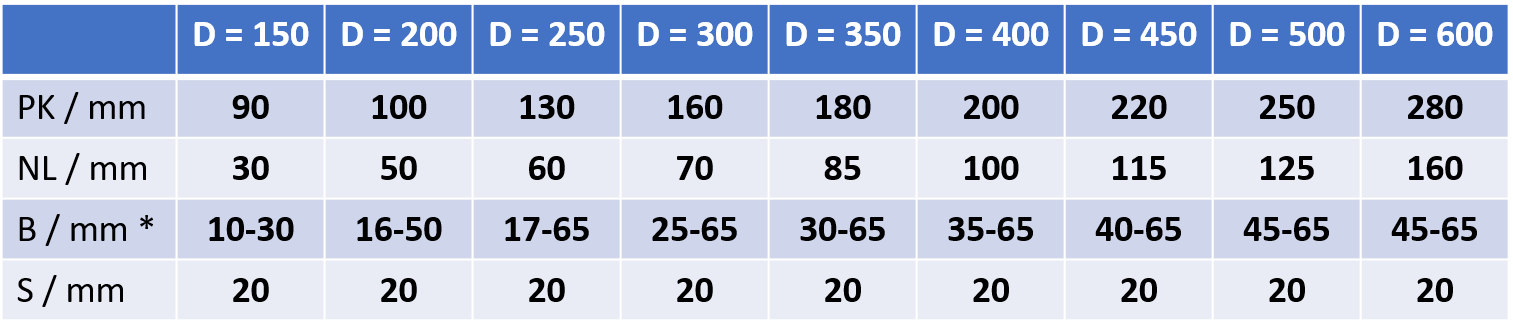

Dimensions

- *Observe safety regulations for the minimum diameter of drive shafts!

Bore Holes

- We manufacture your desired bore individually for you. We cover every known bore diameter for industrial polishing machines *

- If you need other bore diameters or special adapters (e.g. for hexagonal shafts, with keyways, etc.), we will be happy to manufacture them on request **

* Polishing discs drilled individually at the customer's request are excluded from exchange or return in accordance with our Terms of Cancellation.

** Observe safety regulations for the minimum diameter of drive shafts!

Areas of Application

- EFFEKTA high-performance buffing wheels with extra soft pleats are particularly suitable for high-end finishing of complex surface geometries of sensitive painted surfaces, including non-ferrous metals and stainless steel.

- The very soft, single-layer folds adapt flexibly to any surface geometry, allowing to deeply immerse the workpieces into the disc. Even with extended contact zones, thanks to the EFFEKTA pleats a performant airstream and thus very effective cooling is ensured.

- EFFEKTA buffing wheels offer a particularly even high gloss, especially in combination with our 100% seams-free technology.

Heat Development of EFFEKTA Buffing Wheels

- Due to their large contact surface, EFFEKTA buffing wheels develop significant frictional heat. With its powerful air flow, EFFEKTA can efficiently remove this excess heat from the work piece

- Materials with low thermal conductivity (e.g. plastics, wood, etc.) tend to quickly overheat. This can be avoided by carefully dosing the immersion depth and polishing time

Trimming Cotton Buffing Wheels

- Careful preparation of the buffing / polishing tool is a prerequisite for an optimal surface result. Please follow our recommendations for trimming cotton buffing wheels

- Used buffing discs should also be dressed again on a regular basis. This is especially true if residues of polishing paste have solidified on the working surface or the buffing wheels are heavily contaminated with material abrasion

General Information on Polishing

- Please follow our link for general tips and advice on polishing

Protective Equipment when Polishing

When grinding and polishing, the work equipment used creates considerable health risks. It is therefore compulsory to wear suitable personal protective equipment for work safety when grinding and polishing. In particular, all rotating polishing and brushing tools may only be operated with suitable covers for reasons of occupational safety.

Wear eye / face protection

The fine dust emanating from polishing is harmful to the eyes. Flying parts can cause serious injuries to the face and eyes.

Wear respiratory protection

Fine dust contaminated with heavy metals and respirable, which can only be retained with suitable respiratory protection, is produced during polishing.

Wear protective clothing

Flying parts can cause sensitive injuries all over the body.

Wear gloves

In general, gloves should be worn when grinding and polishing. If there is a risk of being wound up (e.g. drills, processing small parts, etc.), gloves may be prohibited on the basis of a risk assessment.

Wear ear protection

Due to the noise exposure during grinding and polishing, it is necessary to wear suitable hearing protection on a regular basis.

Details according to Regulation (EU) 2023/988 (GPSR)

Manufacturer

EICKELIT Schleif- und Polierwerkzeuge GmbH, Finkenstr. 66, D-33609 Bielefeld, info@eickelit.de

Responsible Person

Dr. M. Strampfer, Finkenstr. 66, D-33609 Bielefeld, shop@eickelit.com