Sisal/Leather Combination Brush

8-Stranded Sisal Cords /

Leather Stripes

Ø 200 mm - 400 mm

Product description

Sisal-cord-leather brushes are used in the woodworking industry, particularly with the aim of creating a rustic look. Natural wood surfaces are freed from fibers protruding from the wood in just one step after fine processing and at the same time are moistened with the desired amount of oils or waxes.

The effect of the sisal cord leather brushes is based on a combination of mechanical shearing of the wood fibers, a slightly abrasive effect of the natural materials used and the wax bound in them. During processing, the waxes deposited in and on the sisal cords and the leather strips liquefy due to the frictional heat. Thanks to the suction effect of the brush bristles, it acts like a depot and therefore ensures that the wax is separated very evenly. As a result, the wooden surfaces treated with sisal cord leather brushes have a very high-quality and fine surface appearance.

PRODUCT FEATURES

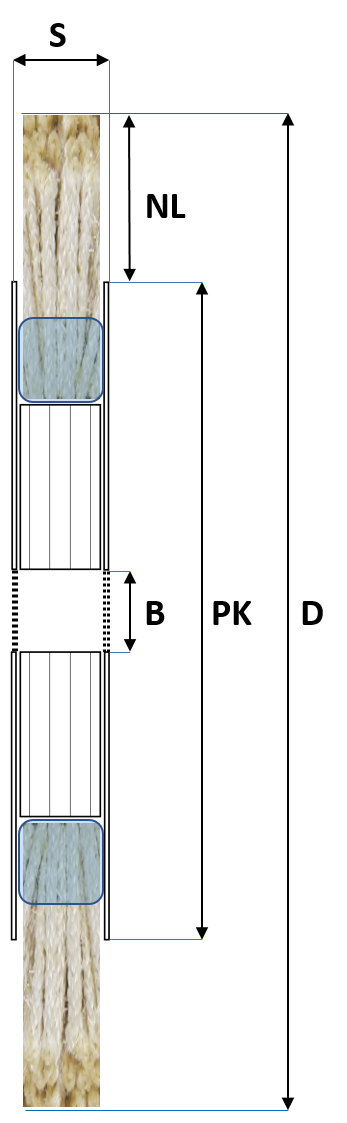

- Layers of 8-strand knotted sisal cords with a thickness of approx. 5 mm

- Evenly distributed strips of untreated cowhide

- The trimmings are fixed to the cardboard core reinforced with phenolic resin with safety stapling made from hard steel staples

- Individually calibrated for low-vibration concentricity and a smooth polishing finish

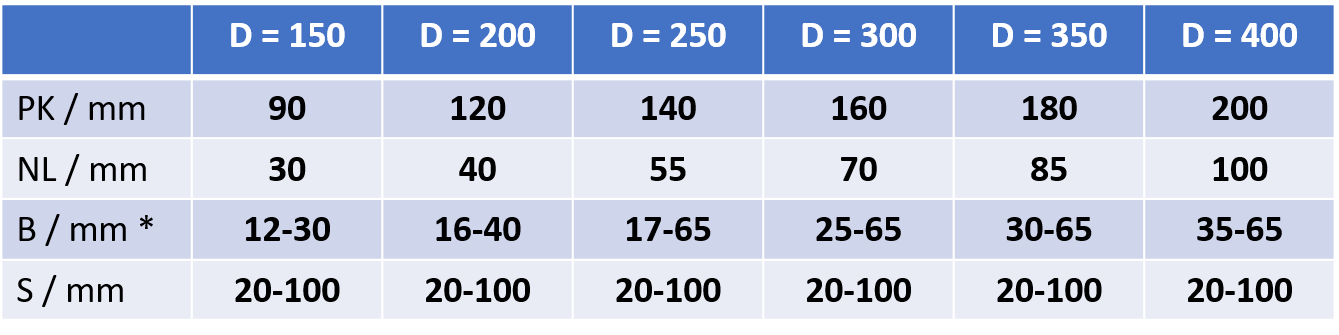

- Diameter configurable from 200 - 400 mm

- Thickness configurable from 20 - 60 mm

- Freely selectable bores 10 - 65 mm