Filament Deburring Brush | SC-006 "Fine" | 200-400 mm

Si-C / Polyamid

"Fine" / Grit 240

Filament Deburring Brush HERKULES

HERKULES abrasive brushes consist of flexible nylon abrasive filaments with embedded silicon carbide or aluminum oxide abrasive crystallites. HERKLUES abrasive brushes are used for a wide variety of materials for deburring, matting, structuring and cleaning. When deburring in particular, abrasive filament brushes have the advantage over conventional metal wire brushes that they grind off the secondary burrs instead of shearing them off. Therefore, deburring with HERKULES brushes provide damage-free contours as required in the manufacture of precise engine and transmission components.

Product Features

- Nylon abrasive filaments casted with a thermoset compound onto a cardboard core

- Incorporated abrasives of SiC or AlOx, grit 80 - 320

- Individually calibrated for vibration-free concentricity

- Diameter 200 to 400 mm

- Witdth 10 to 60 mm

- Freely selectable bore holes 17 - 60 mm

Abrasive Filaments

The filaments of our HERKULES abrasive brushes are made of particularly resistant polyamide 6.12, in which the silicon carbide or aluminum oxide abrasive is embedded. PA 6.12 has high wear and impact resistance, good recovery capacity after bending and is very resistant to oils, greases, aliphatic hydrocarbons and alkalis. PA 6.12 is therefore particularly suitable for use in grinding brushes. For gentle surface treatment, the filaments are extruded in a wave shape.

Abrasive filament SC-006

- Wavy filament made of technically high-quality carrier material PA 6.12

- Silicon carbide grit 240 abrasive

- Thickness: 0.75 mm

Carborundum / Silicon Carbide (SiC)

In contrast to corundum (aluminum oxide / AlOx), the carborundum (silicon carbide / SiC) used in abrasive fleece consists of very sharp-edged crystals. This is the best choice when the fundamentally harder and more brittle properties of SiC are required because the SiC abrasive grains consist of only a few crystallites with a precisely adjusted size distribution. As a result, abrasive nonwovens based on SiC are sharper compared to aluminum oxide and provide more effective removal. The industry uses abrasive fleece based on SiC due to its hardness, especially on non-ferrous metals, stainless tool steels and ceramic and mineral materials.

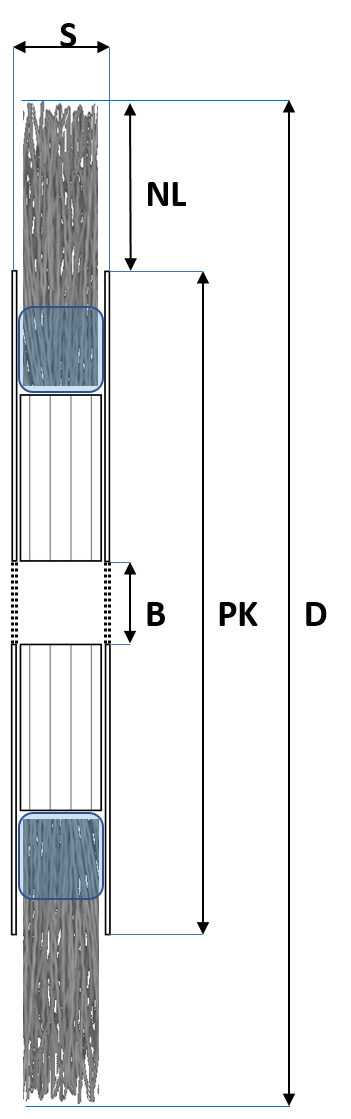

Dimensions

- * Observe safety regulations for the minimum diameter of drive shafts!

Bore Holes

- We manufacture your desired bore individually for you. We cover every known bore diameter for industrial polishing machines *

- If you need other bore diameters or special adapters (e.g. for hexagonal shafts, with keyways, etc.), we will be happy to manufacture them on request **

* Polishing discs drilled individually at the customer's request are excluded from exchange or return in accordance with our Terms of Cancellation.

** Observe safety regulations for the minimum diameter of drive shafts!

Areas of Application

- HERKULES abrasive brushes are suitable for professional deburring, polishing, cleaning & derusting, structuring, rounding off metal surfaces and edges

- Commonly used on a wide variety of materials, such as plastics, wood, textiles, stone as well as non-ferrous metals and steel

- In wood processing, HERKULES abrasive brushes produce surface structures with a rustic look

- HERKULES grinding brushes are suitable for use on manual polishing machinery as well as for automated grinding and robot systems

- Recommended cutting speed: 20-30 m / s

Protective Equipment when Polishing

When grinding and polishing, the work equipment used creates considerable health risks. It is therefore compulsory to wear suitable personal protective equipment for work safety when grinding and polishing. In particular, all rotating polishing and brushing tools may only be operated with suitable covers for reasons of occupational safety.

Wear eye / face protection

The fine dust emanating from polishing is harmful to the eyes. Flying parts can cause serious injuries to the face and eyes.

Wear respiratory protection

Fine dust contaminated with heavy metals and respirable, which can only be retained with suitable respiratory protection, is produced during polishing.

Wear protective clothing

Flying parts can cause sensitive injuries all over the body.

Wear gloves

In general, gloves should be worn when grinding and polishing. If there is a risk of being wound up (e.g. drills, processing small parts, etc.), gloves may be prohibited on the basis of a risk assessment.

Wear ear protection

Due to the noise exposure during grinding and polishing, it is necessary to wear suitable hearing protection on a regular basis.

Details according to Regulation (EU) 2023/988 (GPSR)

Manufacturer

EICKELIT Schleif- und Polierwerkzeuge GmbH, Finkenstr. 66, D-33609 Bielefeld, info@eickelit.de

Responsible Person

Dr. M. Strampfer, Finkenstr. 66, D-33609 Bielefeld, shop@eickelit.com

SiC / Polyamide

"Coarse" / Grit 120