Corrugated Abrasive Fleece Disc | Grit 240 "Fine" AO-006 | Configurable

AlOx / "Finde" / Grit 240

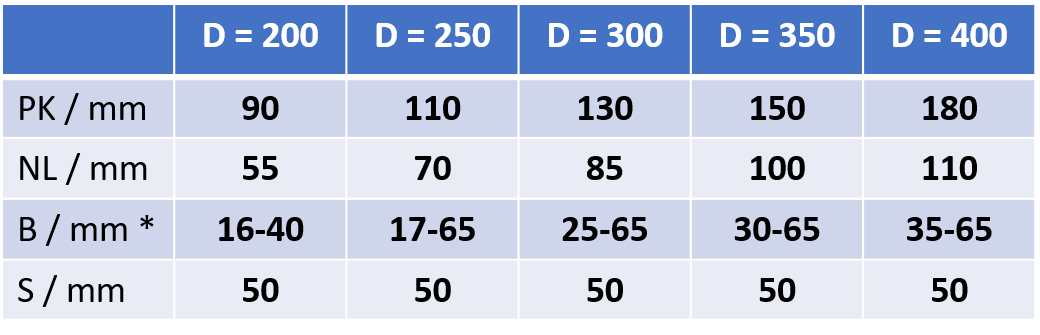

Ø 200 mm - 400 mm

Thickness: 50 mm

Abrasive FLEECE corrugated polishing DISCS for cleaning and matting | AO-006 "Fine"

EICKELIT corrugated abrasive fleece polishing discs are ideal for cleaning and matting large areas of non-ferrous metals and stainless steel. The corrugated shape creates a strong cooling air flow, which optimizes the efficiency and durability of the polishing disc. The flexible fleece also allows even processing of shaped surfaces. Our selection of raw materials offers a wide variety of hardness levels and sanding thicknesses, each made from aluminum oxide and silicon carbide.

PRODUCT FEATURES

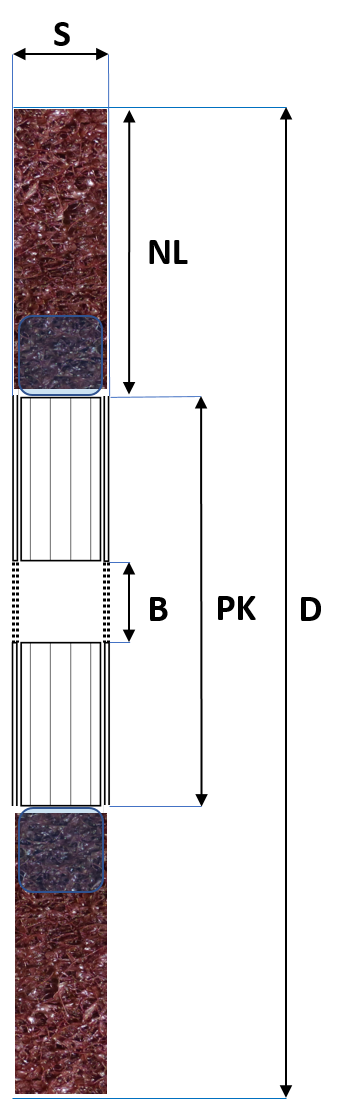

- Three layers of abrasive fleece, laid in wide waves around a solid cardboard core

- Diameter configurable from 200 - 400 mm

- Trim width approx. 50 mm / core thickness approx. 30 mm

- Freely selectable holes 10 - 60 mm

FIBER ABRASIVE FLEECE

- During the production of abrasive fleece, abrasive particles such as silicon carbide ("carborundum") or aluminum oxide ("corundum") are attached to a nylon fiber felt fabric using synthetic resin. The strength and cooling effect of the abrasive fleece therefore depend on the fiber density, the fiber density and the physical-chemical properties of the binding agent used.

- Due to its open construction, the fiber abrasive fleece is self-cleaning and is therefore not blocked during polishing. In addition, the chemical and physical resistance of the fiber composite is suitable for both dry use and for applications in combination with aqueous or oily media.

- As the random fleece is very flexible, it enables efficient processing of complex profiles and geometries with gentle removal. Due to the constant wear of the carrier material, fresh abrasive particles are continuously released in a uniform concentration on the surface of the tool. Polishing tools made of fiber abrasive fleece are therefore particularly low-maintenance and provide a constant and even grinding pattern throughout their entire service life.

- Please follow the link for further information on our range of available abrasive fleece variants

ALUMINUM OXIDE (AO) / "CORUNDUM"

Corundum consists largely of aluminum oxide and is the most common abrasive. With a higher quality, the hardness and brittleness increase, but this has an adverse effect on the longevity of the abrasive grain and thus on the uniformity of the grinding pattern. This is why we mainly use abrasive fleece with doped and consequently tougher types of corundum. This not only increases the service life of the polishing tools, but also generally provides a more balanced grinding result compared to undoped aluminum oxide.